INFORMATION

Professional Blog

Professional Blog

HOME > INFORMATION >

HOME > INFORMATION >

C18665 copper-magnesium alloy coil: high-reliability automotive electronics solutions and China’s intelligent manufacturing advantages

C18665 copper-magnesium alloy coil: high-reliability automotive electronics solutions and China's intelligent manufacturing advantages

Revolutionizing pre-tinning processes to empower next-generation electric transportation systems

In an era of rapid development of new energy vehicles and intelligent electrical devices, C18665 copper-magnesium alloy is becoming a core material for high-end connectors due to its comprehensive performance advantages. As a leader in pre-tinned copper alloy technology, our company provides an in-depth analysis of the properties and applications of this star material, showcasing the global competitiveness of China's supply chain.

Superior Performance: Redefining the Standard for Connector Materials

C18665 (CuMgP) achieves a breakthrough balance through precise magnesium-phosphorus ratio:

✅ Excellent conductivity and strength: while maintaining 80% IACS high conductivity, the tensile strength reaches over 500MPa

✅ Extreme environmental stability:

- Industry-leading stress relaxation resistance (100°C x 1000hr retention rate > 90%)

- Excellent resistance to stress corrosion cracking (SCC)

- Million-level fatigue life guarantee

✅ Surface treatment adaptability: specially optimized for HOT DIP TIN (hot dip tinning) process to achieve:

- Ultra-low whisker risk (compliant with IEC 60068-2-82)

- Mirror-grade surface quality (Ra≤0.2μm)

- Lead-free solder compatibility

Disruptive Application of Pre-Tinned C18665

Through the pre-plating HOT DIP TIN process (plating layer 1.2-2.5μm), we provide:

1. Pre-plated C18665 (CuMgP) – 0.826mm × custom width

2. Pre-plated C18665 (CuMgP)R570 – 0.818mm × custom width

These ready-to-use materials are driving the electrification revolution in transportation:

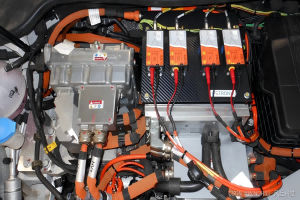

High-voltage systems for e-mobility

- High-voltage terminals for electric vehicles/hybrid vehicles (600V+ ambient)

- Battery module connector, fuse terminal

- Charging pile busbars

High reliability electronic control unit

- Relay reed (anti-shock and vibration)

- Compact switch contacts

- Lithium battery protection board conductive parts

Intelligent power distribution system

- Intelligent circuit breaker contact spring

- Relay box high current carrying parts

- Photovoltaic junction box core conductor

Breakthrough of three major technical barriers of HOT DIP TIN process

The HOT DIP TIN technology we use achieves key breakthroughs:

1. Gradient coating control: Tin-iron alloy transition layer enhances bonding strength (>15N/mm)

2. Whisker suppression technology: 10-year zero-whisker guarantee through stress relief treatment

3. Reflow self-leveling: surface tension automatically repairs micro-defects after soldering

|

|

|

Global supply advantages of China's manufacturing

As a professional manufacturer of C18665, we build irreplaceable supply chain value:

Capacity guarantee:

- Monthly production of 500 tons of C18665 strip (including pre-tinned products)

- Support full-size customization from 0.1-1.5mm×5-300mm

Technical response:

- Provide coating solution verification within 48 hours

- Free application scenario simulation report

Cost competitiveness:

- Vertically integrated mining → refining → alloying chain

- Reduce logistics costs by 30%+ compared to imported materials

---

Upgrade your material solutions now

Whether you need:

✅ Pre-tinned C18665 coil (supports JIS/GB/ASTM standards)

✅ Customized HOT DIP TIN process parameters

✅ Support for VDA6.3 certification of automotive electronic materials

Contact us for free samples and the "White Paper on C18665 Applications in High-Voltage Connectors." Let China-made C18665 alloy become your "conductive armor" for conquering the global market!