Application Cases

Application Cases

HOME > TECHNOLOGIES >

HOME > TECHNOLOGIES >

C70310 application and prospects of high-performance materials

2024-12-19

C70310 copper-nickel-silicon alloy strip: application and prospects of high-performance materials

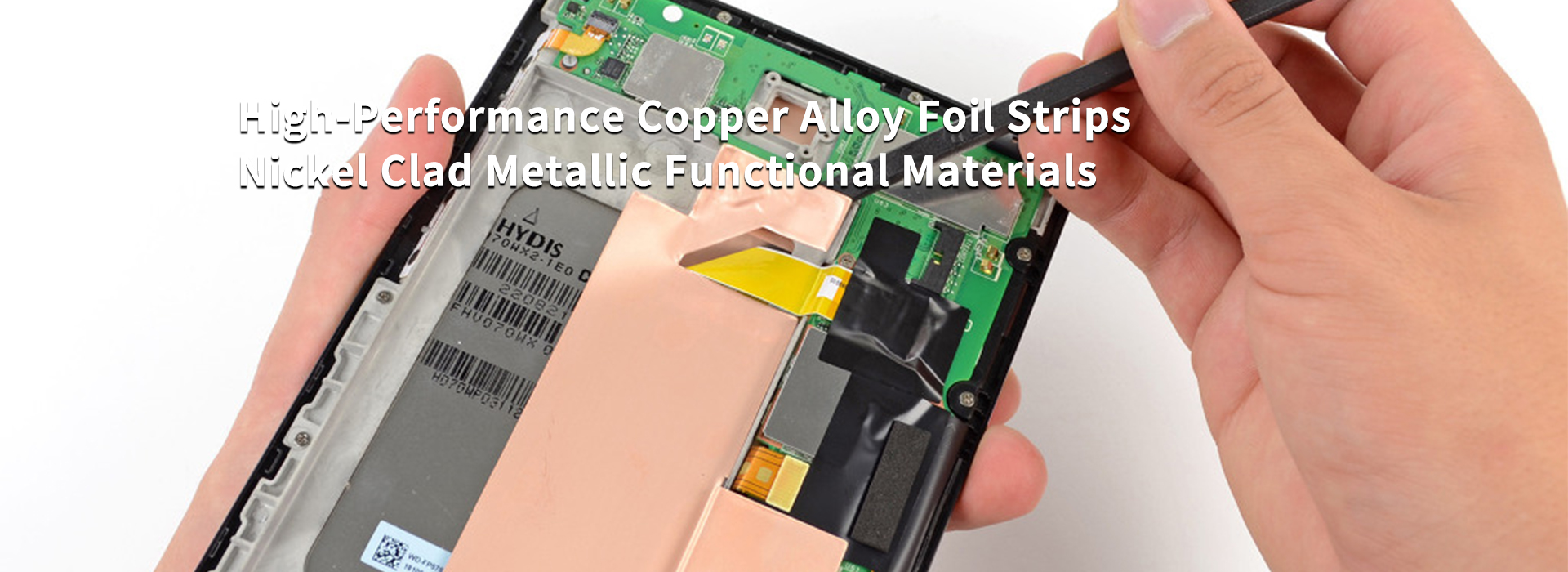

C70310 copper-nickel-silicon alloy strip, as a metal material with excellent performance, is widely used in fields that require high strength, excellent bendability and good conductivity. Its unique characteristics make it a place in many high-end industries. Shenzhen UrbanMines Alloy Co., Ltd. specializes in the research and development of high-performance copper alloy foil strips and provides technical solutions for customers. The company's R&D department has compiled this article to deeply explore the prospects and potential of C70310 alloy strip from the aspects of production principles, technical processes, alloy advantages, specific applications, market trends and industry analysis.

1. Production principles and technical processes

C70310 alloy strip is mainly composed of three elements: copper, nickel and silicon, among which copper is dominant, and nickel and silicon are the main alloying elements. This alloy is produced through precise metallurgical processes to ensure its high stability and consistency in performance.

Production process:

Melting and alloying : First, copper, nickel and silicon are precisely mixed in a predetermined proportion, and electric furnace melting technology is used to ensure uniformity during the melting process and sufficient dissolution of the alloy elements.

Casting and heat treatment : After the alloy is melted, it is cast to form ingots or sheets, from which it is made into strips through a hot rolling process. At this stage, the grain structure of the material is optimized to ensure high efficiency in its subsequent processing.

Cold working and aging hardening : The cold rolling process enables the alloy strip to obtain the required size and surface finish, and the aging treatment improves its tensile strength and fatigue resistance. This process not only enables the C70310 alloy strip to have good mechanical properties, but also effectively avoids relaxation during long-term use and maintains the stability of the material.

Through this series of precise production processes, C70310 alloy strip can obtain the required mechanical properties, chemical stability and electrical properties.

2. Alloy advantages

C70310 copper-nickel-silicon alloy strip has shown its unique advantages in many aspects:

High tensile strength : During the aging hardening process, the tensile strength of C70310 alloy strip can be significantly improved, which is much higher than pure copper and traditional copper alloy materials. This makes it perform particularly well in environments with high loads.

Excellent bendability : The alloy has excellent plasticity and toughness, and can complete complex bending processing without breaking, making it suitable for the manufacture of precision electronic components.

Good electrical conductivity : Despite the addition of alloying elements such as nickel and silicon, C70310 still maintains high electrical conductivity, which is particularly important for applications in the electrical and electronic fields.

Anti-relaxation performance : C70310 alloy strip has good anti-relaxation performance, and its size and performance change little even under high temperature or long-term load conditions. This feature has great advantages in high-precision equipment that requires long-term stable use.

Corrosion resistance : The addition of nickel and silicon enhances the corrosion resistance of C70310 alloy, especially in wet or chemical-containing environments, showing higher durability.

3. Specific Applications

C70310 copper-nickel-silicon alloy strip is widely used in many high-end fields, especially in environments with high material performance requirements. The following are its main application areas:

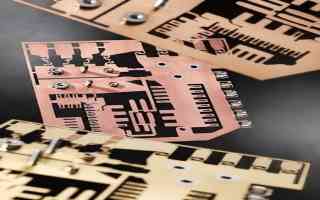

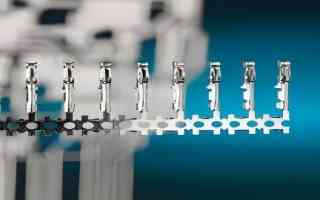

Electronics Industry : Due to its good conductivity, corrosion resistance and high strength, C70310 is widely used in the manufacture of precision electronic components such as connectors, electronic switches, contact materials, etc.

Automotive industry : In electric vehicles (EV) and traditional fuel vehicles, C70310 alloy strip can be used for high-performance battery connection components, electrical wiring systems and electronic control units.

Communications industry : Used to manufacture contact points, joints, cable connectors and other components of high-frequency transmission equipment. Especially in 5G communications equipment, C70310 alloy strip is favored for its excellent conductivity and strength.

Aerospace : In the fields of spacecraft, satellites, etc., the anti-relaxation performance, high temperature resistance and high strength of C70310 alloy make it an ideal material for key components.

Precision instruments : Springs, contact elements and electrical connection parts in high-precision mechanical equipment often use C70310 alloy strip due to its excellent elasticity and strength.

4. Market dynamics and industry analysis

With the continuous development of science and technology, the demand for high-performance metal materials continues to increase, especially in the electronics, electricity, communications, automobile and other industries. The market demand for C70310 copper-nickel-silicon alloy strip shows a steady growth trend.

Electronic and electrical field : With the continuous development of technologies such as 5G communications, artificial intelligence, and the Internet of Things, the demand for high-performance alloy strips is particularly strong. C70310 alloy has great market potential in this field, especially in high-frequency electronic components, connectors, contact materials, etc. The demand continues to increase.

Automobile industry : With the rise of new energy vehicles, the demand for high-performance materials for battery connectors, electronic control systems and electric drive systems has increased significantly, and C70310 alloy has broad application prospects in this field. In the future, C70310 alloy is expected to become an important material for key components in the automotive manufacturing industry.

Global competition and raw material supply : With the continuous development of global manufacturing, especially in emerging markets such as China, India and Europe, the demand for C70310 alloy is growing. This has promoted the competition among relevant raw material suppliers and alloy strip manufacturers, and also required enterprises to continuously improve production processes and technological innovation to maintain market competitiveness.

Environmental protection and sustainability : In the context of increasingly stringent green manufacturing and environmental protection requirements, C70310 copper-nickel-silicon alloy strip has become an environmentally friendly material advocated by more and more industries due to its durability, long life and low energy consumption, especially in high-end equipment and high-tech industries.

5. Conclusion

C70310 copper-nickel-silicon alloy strip has become an indispensable material in many high-tech industries due to its high strength, excellent bendability, good conductivity and excellent anti-relaxation performance. With the increasing global demand for high-performance materials, C70310 alloy strip has broad application prospects in electronics, automobiles, aerospace and other fields. Its stable production process and continuous innovation of technology indicate that this alloy strip will continue to maintain strong market demand in the future, providing more efficient and reliable solutions for all walks of life.

For manufacturers, strengthening R&D and improving product quality will give them an advantage in global competition. For end users, C70310 copper-nickel-silicon alloy strip will undoubtedly be one of the preferred materials for the manufacture of high-performance products in the future.

C70310 copper-nickel-silicon alloy strip, as a metal material with excellent performance, is widely used in fields that require high strength, excellent bendability and good conductivity. Its unique characteristics make it a place in many high-end industries. Shenzhen UrbanMines Alloy Co., Ltd. specializes in the research and development of high-performance copper alloy foil strips and provides technical solutions for customers. The company's R&D department has compiled this article to deeply explore the prospects and potential of C70310 alloy strip from the aspects of production principles, technical processes, alloy advantages, specific applications, market trends and industry analysis.

1. Production principles and technical processes

C70310 alloy strip is mainly composed of three elements: copper, nickel and silicon, among which copper is dominant, and nickel and silicon are the main alloying elements. This alloy is produced through precise metallurgical processes to ensure its high stability and consistency in performance.

Production process:

Melting and alloying : First, copper, nickel and silicon are precisely mixed in a predetermined proportion, and electric furnace melting technology is used to ensure uniformity during the melting process and sufficient dissolution of the alloy elements.

Casting and heat treatment : After the alloy is melted, it is cast to form ingots or sheets, from which it is made into strips through a hot rolling process. At this stage, the grain structure of the material is optimized to ensure high efficiency in its subsequent processing.

Cold working and aging hardening : The cold rolling process enables the alloy strip to obtain the required size and surface finish, and the aging treatment improves its tensile strength and fatigue resistance. This process not only enables the C70310 alloy strip to have good mechanical properties, but also effectively avoids relaxation during long-term use and maintains the stability of the material.

Through this series of precise production processes, C70310 alloy strip can obtain the required mechanical properties, chemical stability and electrical properties.

2. Alloy advantages

C70310 copper-nickel-silicon alloy strip has shown its unique advantages in many aspects:

High tensile strength : During the aging hardening process, the tensile strength of C70310 alloy strip can be significantly improved, which is much higher than pure copper and traditional copper alloy materials. This makes it perform particularly well in environments with high loads.

Excellent bendability : The alloy has excellent plasticity and toughness, and can complete complex bending processing without breaking, making it suitable for the manufacture of precision electronic components.

Good electrical conductivity : Despite the addition of alloying elements such as nickel and silicon, C70310 still maintains high electrical conductivity, which is particularly important for applications in the electrical and electronic fields.

Anti-relaxation performance : C70310 alloy strip has good anti-relaxation performance, and its size and performance change little even under high temperature or long-term load conditions. This feature has great advantages in high-precision equipment that requires long-term stable use.

Corrosion resistance : The addition of nickel and silicon enhances the corrosion resistance of C70310 alloy, especially in wet or chemical-containing environments, showing higher durability.

3. Specific Applications

C70310 copper-nickel-silicon alloy strip is widely used in many high-end fields, especially in environments with high material performance requirements. The following are its main application areas:

Electronics Industry : Due to its good conductivity, corrosion resistance and high strength, C70310 is widely used in the manufacture of precision electronic components such as connectors, electronic switches, contact materials, etc.

Automotive industry : In electric vehicles (EV) and traditional fuel vehicles, C70310 alloy strip can be used for high-performance battery connection components, electrical wiring systems and electronic control units.

Communications industry : Used to manufacture contact points, joints, cable connectors and other components of high-frequency transmission equipment. Especially in 5G communications equipment, C70310 alloy strip is favored for its excellent conductivity and strength.

Aerospace : In the fields of spacecraft, satellites, etc., the anti-relaxation performance, high temperature resistance and high strength of C70310 alloy make it an ideal material for key components.

Precision instruments : Springs, contact elements and electrical connection parts in high-precision mechanical equipment often use C70310 alloy strip due to its excellent elasticity and strength.

|

|

|

4. Market dynamics and industry analysis

With the continuous development of science and technology, the demand for high-performance metal materials continues to increase, especially in the electronics, electricity, communications, automobile and other industries. The market demand for C70310 copper-nickel-silicon alloy strip shows a steady growth trend.

Electronic and electrical field : With the continuous development of technologies such as 5G communications, artificial intelligence, and the Internet of Things, the demand for high-performance alloy strips is particularly strong. C70310 alloy has great market potential in this field, especially in high-frequency electronic components, connectors, contact materials, etc. The demand continues to increase.

Automobile industry : With the rise of new energy vehicles, the demand for high-performance materials for battery connectors, electronic control systems and electric drive systems has increased significantly, and C70310 alloy has broad application prospects in this field. In the future, C70310 alloy is expected to become an important material for key components in the automotive manufacturing industry.

Global competition and raw material supply : With the continuous development of global manufacturing, especially in emerging markets such as China, India and Europe, the demand for C70310 alloy is growing. This has promoted the competition among relevant raw material suppliers and alloy strip manufacturers, and also required enterprises to continuously improve production processes and technological innovation to maintain market competitiveness.

Environmental protection and sustainability : In the context of increasingly stringent green manufacturing and environmental protection requirements, C70310 copper-nickel-silicon alloy strip has become an environmentally friendly material advocated by more and more industries due to its durability, long life and low energy consumption, especially in high-end equipment and high-tech industries.

5. Conclusion

C70310 copper-nickel-silicon alloy strip has become an indispensable material in many high-tech industries due to its high strength, excellent bendability, good conductivity and excellent anti-relaxation performance. With the increasing global demand for high-performance materials, C70310 alloy strip has broad application prospects in electronics, automobiles, aerospace and other fields. Its stable production process and continuous innovation of technology indicate that this alloy strip will continue to maintain strong market demand in the future, providing more efficient and reliable solutions for all walks of life.

For manufacturers, strengthening R&D and improving product quality will give them an advantage in global competition. For end users, C70310 copper-nickel-silicon alloy strip will undoubtedly be one of the preferred materials for the manufacture of high-performance products in the future.