Application Cases

Application Cases

HOME > TECHNOLOGIES >

HOME > TECHNOLOGIES >

Explore high-performance copper alloy UM7035: perfect solution for miniaturization and efficient connection of electronic components

2023-07-01

Explore high-performance copper alloy UM7035:perfect solution for miniaturization and efficient connection of electronic components

As electronic components continue to develop towards miniaturization, high density and high performance, the choice of materials plays a vital role in improving product performance, extending service life and achieving efficient production. Under this trend, UM7035 CuNiCoSi high-performance copper alloy has become an ideal choice for many high-end electronic applications due to its unique physical properties and superior mechanical properties. Especially today when electronic assembly and connection technology are becoming increasingly complex, UM7035 high-performance copper alloy provides strong material support for innovative applications.

**C7035 and UM7035: Twin stars of high-performance copper alloys**

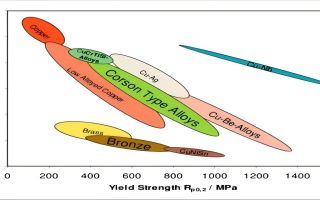

UM7035 alloy shares many similar high-performance properties with C7035 alloy, especially in the miniaturization and efficient assembly and densification of electronic components, showing excellent advantages. C7035 alloy belongs to the Corson alloy family and is famous for its unique melting texture control technology, which ensures its yield strength of up to 1000N/mm², maintains good bending formability, and still has excellent electrical conductivity. It is this technology that makes C7035 alloy the best choice for miniaturization and assembly densification of electronic components.

UM7035 CuNiCoSi high-performance copper alloy is highly similar to C7035 in many aspects, but its performance in many fields has unique advantages, especially in scenarios where high temperature, high strength and high conductivity are required.

**UM7035 core advantages:**

1. **Low elastic modulus and high flexibility contact design**

The low elastic modulus of UM7035 alloy enables it to perform well in applications such as fast battery charging and battery connection. The low elastic modulus not only reduces the hardness of the material, but also enables it to ensure a more flexible contact design in high-frequency and high-temperature environments, effectively avoiding poor contact problems caused by thermal expansion or high-voltage contact.

2. **Excellent stress relaxation resistance**

In applications that require high temperature and high stress, UM7035 exhibits excellent stress relaxation resistance. The alloy's stress relaxation resistance enables it to maintain excellent mechanical properties under high temperature conditions, making it an ideal choice for high temperature environments and widely used in applications with demanding temperature requirements such as battery fast charging systems.

3. **Environmentally friendly, low cost and no need for hardening heat treatment**

The composition of UM7035 alloy is beryllium-free, nickel-free, and environmentally friendly, which greatly reduces the environmental burden during use. More importantly, UM7035 can obtain ideal performance without hardening heat treatment, which reduces production costs while simplifying the manufacturing process and greatly improves production efficiency. Therefore, UM7035 is not only an ideal choice to replace highly elastic materials such as beryllium copper and titanium copper, but also a cost-effective alternative.

4. **Excellent conductivity and high strength**

In terms of electrical conductivity, UM7035 alloy is similar to C7035 and has good electrical conductivity, which can effectively meet the needs of high strength and high conductivity, such as high current connectors, CPU-Sockets and smartphone connectors.

**Typical application areas of UM7035:**

Due to its excellent comprehensive properties, UM7035 alloy has been widely used in many high-tech fields, especially in situations where high strength, high conductivity and stress relaxation resistance are required. Its typical application areas include:

- **Replacing beryllium copper, titanium copper and other high elastic contact materials: ** Under high frequency, high temperature and complex stress environment, UM7035 can effectively replace traditional beryllium copper materials, avoiding the environmental and health risks brought by beryllium copper.

- **Lead Frame and Power Relay:** Due to its excellent conductivity and high temperature resistance, UM7035 alloy has become an important material in power relays and high current connectors.

- **CPU-Socket and USB 3.0/3.1 interface: ** UM7035's high conductivity and good thermal stability enable it to perform well in high-density connection situations, especially suitable for high-performance CPU-Socket and high-speed USB connectors.

- **Smartphone and automotive connectors:** In the fields of smartphones and automobiles, the high strength, low cost and environmental protection characteristics of UM7035 alloy make it an ideal choice for connector materials, meeting the high requirements of modern consumer electronics and automotive electronics.

**Future Development and Application Prospects**

As the research and development of UM7035 CuNiCoSi alloy continues to deepen, its performance will be further improved and optimized. In the future, UM7035 may expand into more application areas, such as high-frequency communications, aerospace, and other electronic connectors in high-temperature and high-current environments. As the electronics industry continues to increase its demand for material performance, the scope of application and market demand for UM7035 alloy will continue to grow, becoming the core material in more high-end applications.

In summary, UM7035 CuNiCoSi high-performance copper alloy has become a key material in the field of high-end electronic components, connectors and other electronic components with its excellent physical and mechanical properties. It not only plays an important role in improving product performance and reducing manufacturing costs, but also shows great advantages in environmental protection and sustainable development. It is one of the indispensable core materials in the future electronics industry.

As electronic components continue to develop towards miniaturization, high density and high performance, the choice of materials plays a vital role in improving product performance, extending service life and achieving efficient production. Under this trend, UM7035 CuNiCoSi high-performance copper alloy has become an ideal choice for many high-end electronic applications due to its unique physical properties and superior mechanical properties. Especially today when electronic assembly and connection technology are becoming increasingly complex, UM7035 high-performance copper alloy provides strong material support for innovative applications.

**C7035 and UM7035: Twin stars of high-performance copper alloys**

UM7035 alloy shares many similar high-performance properties with C7035 alloy, especially in the miniaturization and efficient assembly and densification of electronic components, showing excellent advantages. C7035 alloy belongs to the Corson alloy family and is famous for its unique melting texture control technology, which ensures its yield strength of up to 1000N/mm², maintains good bending formability, and still has excellent electrical conductivity. It is this technology that makes C7035 alloy the best choice for miniaturization and assembly densification of electronic components.

UM7035 CuNiCoSi high-performance copper alloy is highly similar to C7035 in many aspects, but its performance in many fields has unique advantages, especially in scenarios where high temperature, high strength and high conductivity are required.

**UM7035 core advantages:**

1. **Low elastic modulus and high flexibility contact design**

The low elastic modulus of UM7035 alloy enables it to perform well in applications such as fast battery charging and battery connection. The low elastic modulus not only reduces the hardness of the material, but also enables it to ensure a more flexible contact design in high-frequency and high-temperature environments, effectively avoiding poor contact problems caused by thermal expansion or high-voltage contact.

2. **Excellent stress relaxation resistance**

In applications that require high temperature and high stress, UM7035 exhibits excellent stress relaxation resistance. The alloy's stress relaxation resistance enables it to maintain excellent mechanical properties under high temperature conditions, making it an ideal choice for high temperature environments and widely used in applications with demanding temperature requirements such as battery fast charging systems.

3. **Environmentally friendly, low cost and no need for hardening heat treatment**

The composition of UM7035 alloy is beryllium-free, nickel-free, and environmentally friendly, which greatly reduces the environmental burden during use. More importantly, UM7035 can obtain ideal performance without hardening heat treatment, which reduces production costs while simplifying the manufacturing process and greatly improves production efficiency. Therefore, UM7035 is not only an ideal choice to replace highly elastic materials such as beryllium copper and titanium copper, but also a cost-effective alternative.

4. **Excellent conductivity and high strength**

In terms of electrical conductivity, UM7035 alloy is similar to C7035 and has good electrical conductivity, which can effectively meet the needs of high strength and high conductivity, such as high current connectors, CPU-Sockets and smartphone connectors.

|

|

|

**Typical application areas of UM7035:**

Due to its excellent comprehensive properties, UM7035 alloy has been widely used in many high-tech fields, especially in situations where high strength, high conductivity and stress relaxation resistance are required. Its typical application areas include:

- **Replacing beryllium copper, titanium copper and other high elastic contact materials: ** Under high frequency, high temperature and complex stress environment, UM7035 can effectively replace traditional beryllium copper materials, avoiding the environmental and health risks brought by beryllium copper.

- **Lead Frame and Power Relay:** Due to its excellent conductivity and high temperature resistance, UM7035 alloy has become an important material in power relays and high current connectors.

- **CPU-Socket and USB 3.0/3.1 interface: ** UM7035's high conductivity and good thermal stability enable it to perform well in high-density connection situations, especially suitable for high-performance CPU-Socket and high-speed USB connectors.

- **Smartphone and automotive connectors:** In the fields of smartphones and automobiles, the high strength, low cost and environmental protection characteristics of UM7035 alloy make it an ideal choice for connector materials, meeting the high requirements of modern consumer electronics and automotive electronics.

**Future Development and Application Prospects**

As the research and development of UM7035 CuNiCoSi alloy continues to deepen, its performance will be further improved and optimized. In the future, UM7035 may expand into more application areas, such as high-frequency communications, aerospace, and other electronic connectors in high-temperature and high-current environments. As the electronics industry continues to increase its demand for material performance, the scope of application and market demand for UM7035 alloy will continue to grow, becoming the core material in more high-end applications.

In summary, UM7035 CuNiCoSi high-performance copper alloy has become a key material in the field of high-end electronic components, connectors and other electronic components with its excellent physical and mechanical properties. It not only plays an important role in improving product performance and reducing manufacturing costs, but also shows great advantages in environmental protection and sustainable development. It is one of the indispensable core materials in the future electronics industry.